|

| C

O N S T R U C T I O N L O G |

|

| J

A N U A R Y 2 0 0 5 |

|

|

| Nothing

was done since December 3, better get going! 841 hours of labor so far... |

|

| 7 |

|

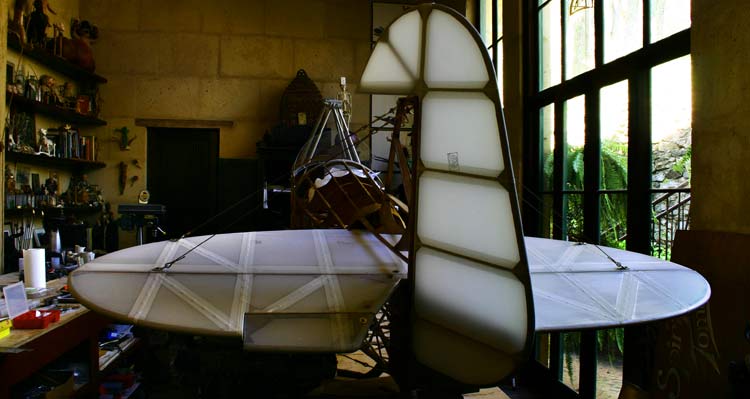

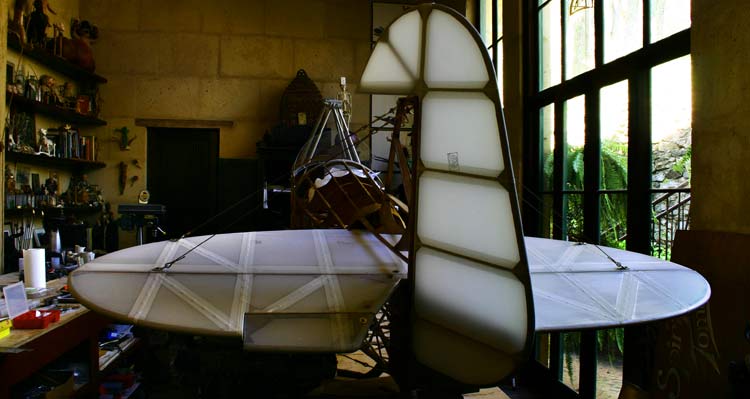

Cut

scallops in leading edge ply, and spackled with Aeropoxy. |

|

3

hrs |

|

|

| 11 |

|

Brushed

2 coats of Poly-brush on leading edge, trailing edge , edged

or aileron bay , wing tip bow, and root rib.

Snapped two chalk lines 2" apart on each side of center of leading edge.

Held fabric in place with clamps and trimmed it at trailing edge and aileron

bay.

Glued

fabric along leading edge in a 2" strip of Poly-Tak. Glued

to trailing edge and aileron bay.

Ironed

fabric around the wing tips, trimmed it. Glued fabric to wing tip

bows. It was actually easier than I thought to pull it smooth. |

|

In

order to get the Poly-Tak to soak through the fine weave light

weight fabric when it is pressed into it, I had to thin it

a little with MEK. I brushed about 18" of Poly-Tak at

a time and quickly pressed the fabric into it with the palm

of my hands. If necessary, I used the brush and a little more

glue to press it in.Turned the wing over . Ironed the fabric

over the trailing edge at 225 and glued it to the top

side.

Covered

root rib with fabric and wrapped it around to the top 1" strip.

Trimmed extra fabric with razor blades. Installed aileron push

rod. |

|

Sanded

edge of fabric lightly on leading edge, and brushed some Poly-Brush

on.

Glued

inspection rings for aileron bell crank, and to install aileron

hinge pin. |

|

|

6

hrs |

|

|

| 12 |

|

Cut

and fit two 1/8"plywood plates with an elongated hole around

the rudder push/pull rods . Used spacers to make it level with

the bottom longeron.

|

|

3

hrs |

|

|

| 13 |

|

Received

my Mitchell oil pressure and oil temperature gauges from Aircraft

Spruce today , both with 1/8NTP sensor, as well as a 1/8NTP to

10/1 mm metric adapter that will fit the pressure sensor. I still

need to find a 1/8 NTP TO 10/1.5 mm adapter for the temperature

probe. |

|

I

have exchanged e-mails with Westach about a dual 2 1/4" square

CHT gauge Model 2DA8( $103.30), and two 12mm spark plug thermocouples

type 710-8WK ($16.60 each), plus $8.40 per red arc marking .

Aircraft Spruce actually sells the same gauge for only . $79.25. That

would leave a slot open for the Mitchell Voltmeter.

The other option would be to use 2 single CHT gauges and no

voltmeter. |

|

Also

received my 72" Warp Drive prop with its two skinny black

square tiped carbon fiber blades. It is not exactly ugly, but

I still long for an old fashion 2 color laminated wood prop with

wide rounded blades... |

|

Finally

got my engine mounting plates back from the tin shop. Sanded

them shiny.

Attached the Lord mounts with AN3-4A bolts , and attached the assemblies

to the engine with 10 mm-1.5 x 50 mm metric X head bolts and washers. |

|

|

2

hrs |

|

|

|

|

| 17 |

|

In

order to move the engine as close to the firewall as possible,

I had to cut a hole in the boot to make space for the oil outlet

to the cooler and the oil pressure sensor. The protrusion will

be covered with a metal cup. A 90 degree fitting at the oil outlet

toward the forward mounted oil cooler would help too and keep

the rubber hose from protruding between the pedals. |

|

Made

sure the prop was lined up with the fuselage center line and

square .

Turned the prop vertical and checked it with a level.

Turned it to a horizontal position and measured from each

tip to the sides of the firewall and to the tail wheel bolt. These measurements

are within 1/4". |

|

Bolted

the engine mount frame to the firewall. Placed the cross member

above the foot wells in the boot. Cut the slanted 5/8" square

tubing pieces to attach the two motor mount plates to that cross

member.

I find that with the prop hub centered, the engine mount supports

are offset about 1/4 " to the right. Checked and rechecked measurements

and squareness. I will have to call Steve and Jamil about this. The engine does

not seem to be symetrical. |

|

Got

a 3 1/2 x 12 ft carpet remnant to pad the top of my outside work

table, to avoid abrasions when moving the covered wings.

Cleaned up extra Poly-tak with MEK. Trimmed fabric with razor

blades along trailing edge and wing tip bow.

Heated iron to 250, and tightened up the fabric, starting

at the ends of the wings toward the center, and working on each side in turn,

to avoid warping. Ironed seams and smoothed small wrinkles and lumps . |

|

|

8

hrs |

|

|

| 18 |

|

Decided

to start the engine installation over with more precision. Went

to Home Depot and bought a good 12" level(I checked them

for precision and picked the best), and a long perfectly straight

flat aluminum bar .

Re-leveled the fuselage and held it in place with wood squares

screwed into the table.

|

|

Rechecked

all the center marks with square and level all the way down

the top of the fuselage. Verified all the center marks

lined up from the tail fin to the firewall with the long ruler

and clamped it in place so the front end sticks out just past

the front of the prop.

|

|

Adjusted

angle of the blades of the prop so the tips are vertical.

Marked the center line of the prop on the hub, as well

as a line at right angle going through the exact center of rotation. Turned the

prop horizontal until that cross line is perfectly vertical , and lined it up

with the end of the stick marking the center line of the fuselage. |

|

Using

a long ruler clamped in turn to each side of the fuselage, marked

on the blocks of wood supporting the engine the extension of

the longerons. |

|

These

marks are 24" apart( the width of the fuselage). Marked

the mid point on the cross piece supporting the front of the

engine and keeping it level front to back. The back ends of both

mounting plates touch the tip of the boot, so the thrust line

of the engine is in line with the fuselage. Leveled the engine

side to side using the mounting plates as a reference. |

|

Checked

that the center fin on the bottom of the crank case lines up

with the center mark on the cross piece supporting the front

of the engine. It does, but the mounting plates are off about

1/8". |

|

Measured

with a tape measure the distance from the tail wheel bolt to

each tip of the prop, and made sure they were equal within 1/16 ".

Checked the distance between the vertical members of the engine

mount and the tips of the prop. They are within 1/8". Put a small nail on

the center on top of the firewall, and measured to each tip of the prop. They

are less than 1/8".

I didn't think I could do much better, so I adjusted the 5/8" square

tubing pieces to fit. I will tack it all in place to morrow. |

|

While

the sun is out and it is not too cold, I set up my carpeted table

outside and ironed the covered wing at 350 degrees. Everything

pulled nice and tight .

Ironed the seams some more at 250, and wiped them smooth with

MEK. It will take some more work with the small iron to smooth out all the lumps

and bubbles. |

|

|

8

hrs |

|

|

| 19 |

|

With

the engine bolted in position, tacked the 5/8" square

tubing supports to the mounting plates , and the slanted pieces

to the cross member of the frame.

Cut

the 1/2" round top braces, beveled them to fit , and tacked

them to the square supports. |

|

Because

the right cylinder is closer to the firewall than the left,

the brace on the right side is shorter than the one on the

left, and I doubled it for strength .

Cut

and beveled the bottom braces , and tacked them in place.

Cut

and tacked in a piece of round tubing to connect the front

ends of the mounts and keep them at a proper spacing. |

|

The

engine was then unbolted from the mounts, and the assembled engine

mount pulled back and away from the motor with the whole fuselage,

lifting the tail way up to clear the front cross brace.

There

is an issue I want to discuss here and will talk to Gene about .

Is it better to insert the bolt from the front and screw it into

a 2 lug fiber nut attached to the vertical member by 2 screws over

an aluminum plate, as shown on the left? That would make removal

of mount easier after the ply sides are glue on. |

|

Or

is it preferable to insert the bolt from the rear of the firewall

with big washers or a plate, and use the fiber nut at the front

of the firewall, where it can be seen? Removal of mount would

then require a wrench behind the firewall.

If I do that, should I consider using drilled bolts , and epoxying

them in? |

|

Also,

should the 1/4" holes in the vertical members be redrilled

at 3/8" and fitted with aluminum or steel inserts? I will

ask Gene to morrow.

I

took the assembled engine mount off, removed the Lord mounts,

and took it to my welder, with some 1/16" weldind rods

of 4130 chrome alloy steel . |

|

|

8

hrs |

|

|

| 20 |

|

Gene

says to leave the holes 1/4" ( no sleeves) and to insert

bolts from the front and use 2 lug nuts behind the firewall.

Went

by harbor freight to buy new horses, and ended up buying two

folding stands instead, which are perfect to lay the wings

on to varnish or rib stitch. They have a section of padding

covering the tubing on the top . |

|

Gave

a soaked in fill coat of Poly-Brush to both sides of the wing,

after some more smoothing at 250 with the small iron. |

| |

Removed

the panel to start installing the rest of the instruments.

Got

some small brass acorn nuts and brass screws to mount the 2 1/4" gauges.

Mounted

the gas gauge in the center.

Still debating whether to

use a dual CHT and a voltmeter, or 2 single CHT gauges. |

|

|

5

hrs |

|

|

| 21 |

|

Lightly

sanded the second lower wing and gave 2 coats of Poly-Brush to

the wood areas that will touch fabric.

Snapped a chalk line 1" up from the center

line of leading edge, and taped with 1" masking tape

. Trimmed fabric, pulled it to fit and clamped it on the trailing

edge .

Brushed a 2" strip of Poly-Tak on and quickly

pressed the fabric in it firmly with the palm of the hand in 18"

sections. Used the brush to press in the areas where the glue

has not sufficiently soaked through. |

|

I

learned doing the first wing that to get a wrinkle free transition

to the wing tip bow curve , it helps to pull the last few inches

up over the chalk line. |

|

Turned

the wing over and glued the fabric along the trailing edge,

the bow, and to the 1" root strip. Let it dry for a while.

Smoothed

the extra glue with MEK. |

|

Turned

wing over, and work fabric over trailing edge with the small

iron at 250.

Glued

it to the trailing edge . After it dried, trimmed it with razor

blade. |

|

Wrapped

and glued fabric around wing tip bow the same way. Trimmed

along inside edge.

Cleaned

up extra glue with MEK. |

|

While

the glue dried in the sun on my brand new stands, I got out one

of the top wings and sanded it lightly, then gave it the 2 coats

of Poly-Brush . |

|

|

8

hrs |

|

|

| 22 |

|

Took

panel off, and continued installing instruments , switched ,

fuses, and cigarette lighter outlet, making sure to leave a space

where the cabane supports are against the panel.

Used a standard keyed ignition switch, and a separate starter

push button. Instead of using a standard split master switch,

I opted for a pair of good looking aluminum switches from Auto

Zone. The cigarette lighter outlet will allow plugging an eventual

GPS and radio.

I will order the 3 1/8" Westach Tachometer on Monday.

|

|

Decided

to cut out part of the front seat back panel to have easier future

access to the instruments wiring. I will make an aluminum cover

with swirls to match the existing doors. |

|

Added

a spacer to make a little more room for the altimeter, glued

it in with the 4 brass stubs to attach the panel. Also had to

remove some material to insert and fit the two lower gauges down

into the panel floor. It will not weaken the structure, as there

is a doubled cross member there already that was added as a spacer

earlier , and turned

out not to be quite sufficent to fit the altimeter when the panel

was slanted. The seat belt blocks are untouched. |

|

Tentatively

located the Voltage Regulator and the Ignition Control unit on

the right side and top part of the firewall.

Mounted

the oil pressure sender with the metric adapter in place of the

original oil pressure warning light sensor. I might still use

both if I find a T. |

|

Similarly

located the starter relay just above the Starter, and the main

Master Relay to the left of it above the boot.

I

am pretty sure the battery will have to go in the back of the

pilot seat to balance the heavier engine, but it will take about

9 feet of both positive and negative #4 wire to bring the power

from it. It would be so much easier to mount it to the firewall

right above the starter relay... |

|

The

installed panel is marked to be slightly notched at each end

to fit the two cabane supports and mounting bolts. The fit is

very tight.

Decided

to forgo the Voltmeter for a simple light, and to use 2 Mitchell

single CHT gauges, instead of the Westach dual gauge, which looks

too modern for me. Looks count, and I find my panel design

quite hansome thank you...

Now, if I could only find an oil temperature sender in a 10-1.5

mm size , everything would match.

|

|

|

8

hrs |

|

|

| 23 |

|

I

went on E-Bay today and looked a more than a thousand Harley wheels

offered for sale or auction . Realized that I had been looking

for wire spoke wheels because it IS the vintage WW1 thing , but

actually liked the solid look of the aluminum 16" "FAT BOY" wheels

better . They are also lighter and surely withstand side forces

much better . I bit the bullet and bought one front wheel outright

for $100. There are several more coming up in the next few days.

I am not sure of the weight, it will hopefully not be too much

. I will have to see about disk brakes for them now. Will I keep

the landing gear now, or design a new undercarriage? |

|

3

hrs |

|

|

| 24 |

|

The

weather is wonderful, sunny and cold, I called my flight instructor

Bob Schrier , and we settled on a 3.30 lesson, just before sundown.

I practiced take offs on the X-Plane simulator, and

manage a number of them without running off the runway. A good omen

may be, we will see this afternoon.

Called Mitchell to inquire about a 10-1.5mm oil temperature sender.

They gave me the part # PS-211-8046 , which I passed on to Aircraft Spruce, as

well as the PS-211-8154 part # for the two CHT 12 mm ring senders for the two

CHT gauges.

Called Westach to order their #Y2ATH7A 3 1/8" TACHOMETER . That should

do it instrumentation wise.

Went by the tin shop to check if my engine mount had been welded. Not yet, but

the gas tank was ready with the new larger 3/8" NTP flange on the bottom that

will take the standard finger strainer. The top is fitted with a welded square

plate to mount the gas gauge sensor.

I read up my flight manuals until it was time to drive to the airstrip for my

lesson.

Well, we flew around the lake and watched the sun set. Had a great time, and

did pretty well actually. I feel somuch better than in October. Yes, it had been

that long!

|

|

2

hrs |

|

|

| 25 |

|

The

weather is still wonderful, sunny and not so cold.I spent

most of the day outside in the driveway covering wings. Glued

fabric to the top side of an upper wing. Glued

fabric to the other side of the lower right wing. Ran out

of Poly-Tak , and won't get any more till Friday, as for

some reason my order was shipped from California instead

of Georgia.

Notched

the sides of the panel to allow the tight fit of the rear

cabane struts mounting brackets .

Drilled

panel and installed the T-handle gas valve control on the extreme

left side. |

The

cable comes out of the back of the panel , and is routed

against the top of the left longeron, through a hole in the

front panel, and around the front to the gas valve handle.

I want the valve to be open when the handle is

pushed in, and closeit by pulling it, so there is no risk

of cutting the gas off by hitting it accidentally .

I

also decided to raise the front seat throttle quadrant, as there

was a chance to hit the bottom side of the levers with the

toe of the foot when pushing the pilot's left rudder pedal. |

| The

handle the valve came with had the closed position at 90 degrees,

and the open at zero, which would cause binding. I cut a new

one out of a 3/32" scrap of aluminum(actually the square cut

out of the top of the gas tank where the gauge mounts), with

the open and closed positions at 45 degrees. I gave it

only one stop tab as the original, so it does not have one

for the open position. Bad. Also, it works backwards, so I

will make a new one. |

|

|

8

hrs |

|

|

| 26 |

|

Cut

a new lever for the gas valve with 2 positive stops in the full

open and the full closed position.

To

the left is the closed position, with the T handle pulled

out. |

To

the left is the full open position of the lever, with the

T handle fully pushed in.

Drilled

a 1/4" hole and mounted a cable B-NUT for cabin heat. |

| The

front seat throttle quadrant was moved up higher, so the bottom

reversed levers would not interfere with the left rudder pedal. |

Ground

the outside of a threaded plastic plumbing connector to make

it fit inside the antique winged gas tank cap . I will epoxy

it in place after it is screwed on the gas tank so it faces

forward.

I will need a soft rubber gasket

, and an mount an open bent copper or brass tube on top to keep the tank under

pressure from the wind. |

|

|

5

hrs |

|

|

| 27 |

|

Cut

a piece of aluminum to make a cover for the opening cut out

in the back of the panel.

Drew

a 5/8" grid on it , to be a guide when doing an old fashion

"bouchonne" finish on the drill press. Make sure

the backing board is perfectly flat and even.

I

had to figure out on my own how to do this , so here is

my procedure.

|

I

had a small 1" rubber sanding disk with a 1/8" shaft and

a set of 1" adhesive backed sanding disks(150 and 220 grit)I

had bought from a model making catalog to use to grind and

polish small bronze sculptures. The rubber disk did not hold

up, so I made my own out of a cheap plastic 3" pad that came

with a set of 3" disks and fiber pads. I cut it down to 1"with

a knife while rotating on a drill. The quick lock hole in

the center was filled with epoxy, and the whole pad was covered

with epoxy. After it dried, it was sanded smooth and

true on the drill press. It

has to be perfect , otherwise the swirls will be off. It

takes very little to mess things up. |

The

disks are stuck to the pad, and the aluminum plate moved 5/8"

at a time row after row so the swirls overlap. You can either line

up the swirls or offset them 5/16" each row. Press lightly, otherwise

the disk heats up and comes unglued . When it does, you have to

clean the residue completely with lighter fluid, re-sand the

disk lightly and clean it with fluid again before sticking a new

disk on. If the disk is still good, you can try to re glue

it on with Weldwood contact cement (applied sparingly to

keep the disk smooth).

You

may also have to shim the backing board slightly to have

a complete swirl . Blow the dust off the metal and off the

board after each swirl. Experiment with a scrap. |

It

is a lot of fuss, but well worth it to me.

The

cover plate was attached with screws and brass countersunk

finishing washers. That's

it for today, I got to go fly, the weather is still wonderful,

but a storm is coming. |

|

|

5

hrs |

|

|

| 28 |

|

Received

my two Mitchell CHT gauges today , and promptly installed the

into the panel. I am assuming my sensors will ship directly

from Mitchell, since they are special order, but have no comfirmation

of that from Aircraft Spruce. Also received the bus bars, which

are jist 1/16"x 1/2"strips of copper with 8 holes

and no screws or mounting hardware. I think I will use instead

a standard aluminum panel bus bar fron Home Depot. Actually

, use one for the ground and one for the positive , and screw

them into the bottom of the panel.

All I miss now is the tach.

|

Got

an assortment of 16 , 14, 12 and 10 gauge wire in red and

black from Auto Zone, as well as a neat small old fashion

black knob pull switch to turn on the instruments lights,

and wired them through a fuse, even tough I probably will

never need them. But what the heck, they were there! All

the fuses were connected to the power bus bar.

Also wired the posive to the oil pressure

and temperature gauges

through fuses on to the power bus.Connected black leads to them wired

to the ground bus bar.

Used 2 blue wires from the ignition switch

to the blue magneto wires on the engine.

Used

a green wire from the oil pressure gauge to the sender. |

|

|

2

hrs |

|

|

A

number of questions have popped up about engine installation, and Steve

at Central Florida Flyers has been very helpful trying to answer them

:

1. Are my Home Depot 10-1.5 mm

all thread bolts OK to bolt the motor mounts? NO, use grade 12 or atleast

8 . So I ordered from www.boltdepot.com :

Product #6751 , Metric hex bolts, Metric partial thread bolts, Steel grade 10.9,

10mm x 1.5, 50mm

2. Can I turn the prop backward,

since there is so much resistance compared to turning it forward? NO.

3. The gas pump is so high on the front

of the engine and so much higher than the gascolator that I wondered

if there was a need for an electric fuel pump. No, and no primer needed either

.

4. What kind of hose should I use between

the gascolator and the fuel pump

, Aeroquip 303 at 6 bucks a foot, or Aeroquip 601 at 10

bucks a foot? He uses a light weight Aeroquip NAZCAR hose with braided stainless

sleeve and stainless hose clamps.

5. The intake of the gas pump is

on top of it, so there will be a high point on the hose. Is there a chance

for vapor lock . No says Steve, in fact , the loop up keeps it primed.

6. Is the alternator light green

or red? Green.

7. Does he use a split master switch

and separate battery and alternator cuircuits? No, just one Master Switch.

8. Are the two extra little loose

elbows on top of the carbutators

for the choke? Yes, and it needs to be connected with motorcycle cables

and housings, like the throttle. I won't be able to use the stiff Bowden

cable I have. I took an elbow off and still can't figure out how to connect

the choke cables. Verner should supply more detailed instructions.

9. Is the Power Sonic 18AH battery I

bought strong enough. Probably not ,says he, though it depends on the engine

.He uses at least a 21AH. A possible option I suggested was to use an extra

bigger 12 volt auto battery on the ground to crank up the engine at first , then

when it is warm, use the smaller one on the plane. Some people have done that.

10. Using

aluminum bus bars from Home Depot is OK.

11. Where to get a face plate for the prop as

recommended by Warp Drive? He will sell me one for $10. |

|

| 31 |

Wasted

a lot of time today going around motorbike shops trying to find

throttle and choke cables for the Verner.I had not thought that

most were closed on Monday , some had closed down . Ended up getting

a brake cable and two thinner shifting cables from the bicycle shop. |

|

2

hrs |

|

|

| TOTAL 935hrs |

|

|