|

| C

O N S T R U C T I O N L O G |

|

| N

O V E M B E R 2 0 0 4 |

|

|

| Wings

off. About ready to cover, and back at work on the fuselage getting ready

for the engine installation. |

|

| 1 |

Glued

rear plates for top horizontal member.

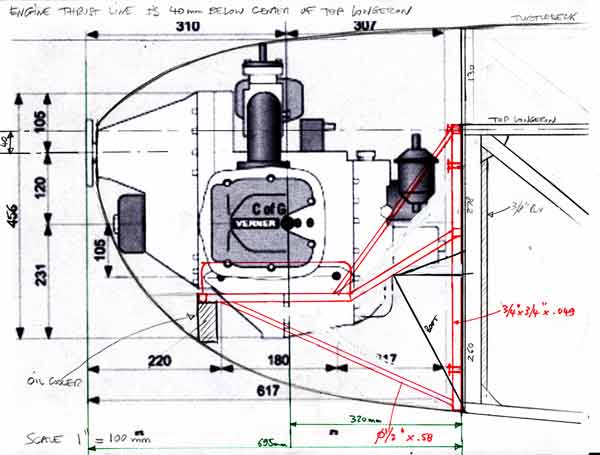

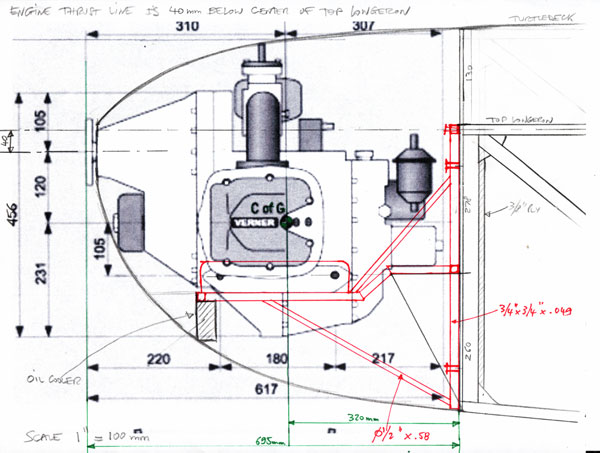

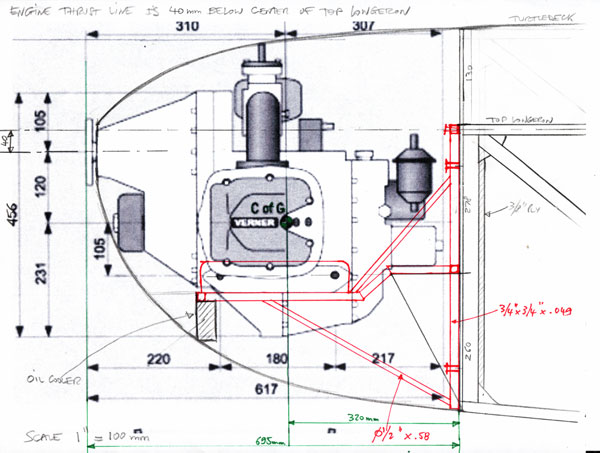

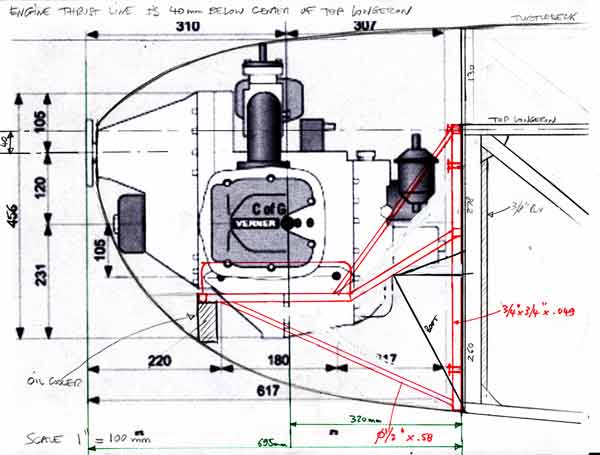

Drew the engine mounted in relation to the firewall, so the

cowling would flow nicely and the CG would be as far back as

possible. Cannot do much better than Jamil. Sent

a copy to Gene with some questions. The e-mail with answers is

below. |

|

Gene,

Here

is a preliminary side view of the VERNER engine installation

on my Classic. As you can see, in order to fit the carburators

inside the aluminum cowling and to keep nice flowing lines,

I have to place the engine thrust line about 1 3/4" below

the center of the top longeron . Is that acceptable?

YES This

is about as close to the firewall as I can get the engine,

and it places the center of gravity of the engine about 13" in front of the

firewall and the prop flange about 27.5" in front of the fire

wall. How does that compare to the 582 installation in your bird,

and does it seem OK to you? The weight of the engine including

all accessories is about 142lbs.

This

is close to what the 582 is, only a little heavier. My

battery is about 12 lbs, should I plan on putting it behind

the pilot seat with a 7 foot #4 battery cable to push the CG

back, or do you think it might be Ok right behind the firewall

between the rudder pedals?

Put

the battery in last. It may have to go behind the seat. I

am not using stringers on the side of the fuselage, and therefore

no curved wood strip on the outside of the front members, so

I re-enforced the front vertical members with two 3/8" plywood strips to the inside and

to the back. I will add a 3/4" square tubing brace across the

top of the engine mount, and put two 1/4" bolts through the top

vertical member, which I also re-enforced with 3/8" plywood

plates in the bolts locations, unless you tell me it's a bad

idea.

Should

be ok

What

kind of welding rods should I use to put the engine mount together,

plain #7, or heat treatable 32CSM. Should the welds be heat

treated? What about the expensive vacuum melted welding wire?

Don't

have an in house welder. Can not answer.

Thanks.

JJ |

|

Even

after a week drying, the epoxy varnish was still lifted

by MEK, so I had to strip it off the 2 ailerons. I will

just glue the fabric directly over the Polyurethane varnish.

Gave

2 coats of Poly-Brush to the leading edge ply, trailing

edge, and end pieces of ailerons.

Started

covering an aileron. Had to start over because I cut

a slit in the fabric on the other side trimming along

the trailing edge piece.

The

straight from the can Poly-Tak is too thick to soak through

the fine weave light weight fabric , so I added some

reducer/ retarder to it, which helps,and also makes it

easier to brush on , and slows the drying some.

Even

working outside, the fumes are making my head and liver

hurt . I may have to shave my beard off to get a good

fit for the respirator... |

|

|

|

4

hrs |

|

|

| 2 |

|

Turned

plane on its side. Designed and started to install heel brakes

to replace the toe brakes. That will allow me to move the pedals

forward of the passenger seat. The bracket supplied by Fisher for

the toe brakes makes a perfect pedal. It is hinged under the floor

through two slots, and the L shaped hinge brackets are bolted to

the rear of the forward landing gear channel , so only the pedal

stick out of the floor. |

|

3

hrs |

|

|

| 3 |

|

Polished

all the heel brake parts. The brake cable goes throuh the floor

at an angle, and through the landing gear chanel, which also stops

the cable housing.

I

hate those cheap looking plywood rudder pedals, and will make new

aluminum ones. |

|

4

hrs |

|

|

| 4 |

|

| Got

a call this morning that my engine had arrived at Fed Ex Freight,

and went to pick it up.After uncrating, I found that the plastic

top of the right carburator and bent aluminum tube guiding

the throttle cable in were broken. Also, the gauges are not

the Verner gauges, and are round

2" type , which will not fit my panel. Steve said I could

return them and buy my own. |

| The

exhaust is not the one shown on the Verner site, and I like

it a lot better . It is a straight swiss type pipe that will

exit at an angle at the bottom of the cowling near the firewall. |

Installed

the old rudder pedals to test the brakes. Had to lengthen

the pull rods with a piece of 1/2" tubing. It feels

pretty comfortable.

So

I bought a piece of 3/16" aluminum to make new rudder

pedals at the Metal Supermarket. They even cut the 4" blanks

for me. Made

the first pedal , with 3/4" holes to lighten them.

I moved the pull rod braket to the back of the pedal and

up a little so it attaches between holes. tThat will shorten

the travel of the pedal a little. The pull rod between

the front and rear pedals will attach to the same bolt |

|

|

4

hrs |

|

|

| 5 |

|

| Made

the remaining 3 pedals and brackets. Went to bigger 1" holes. |

| Installed

the 2 rear pedals. I may move the attach point to the floor back

so the pedals are not so vertical. |

|

|

6

hrs |

|

|

| 6 |

|

| Installed

the front

rudder pedals. Had to notch the top of the boot to fit them. The

boot is really too low for a size 10 foot tomanoeuver the pedals

safely, the toe catches. |

| I

think I will have to cut out a moon shaped section of the firewall

and boot above each pedal and box it with a curved piece of

plywood. That means engine mount lower horizontal piece will

have to move up the firewall. |

|

|

4

hrs |

|

|

| 7 |

|

Started

working on the engine mount, using the 5/8"x .049 wall square tubing

. Drilled tubing and tacked 3/8"x 7/8" long tubing sleeves. Drilled

holes in firewall and

attached the two vertical pieces and the horizontal piece with

long AN4 bolts. Tacked them together.

Redrew

the engine mount to accomodate the taller boot, as shown below.

It actually simplifies the design. Also increase the length of

the 1/2" braces . |

|

4

hrs |

|

|

|

| 8 |

|

| Ordered

a piece

of flat 4130 steel 3"x36" to make the motor mount brackets. |

| Tried

to figure out what gauges to order and what size senders I

need. I like old fashion gauges like the Mitchell oil pressure

and oil temperature square 2 1/4" gauges.The holes

for the senders on the Verner are metric sizes, so I will

probably need adapters for the standard 1/8"NTP

senders. The oil temperature sensor is 10 x 1.5 mm thread with

a 1" tip. The oil pressure, I don't know, and I can't

unscrew the plug, so I sent an e-mail to VERNER to ask. |

| Ion't

like dual CHT gauges a whole lot, but since there is only space

in my panel for five 2 1/4" gauges, I may have

to use one. The alternative is to use a single gauge and switch

from one cylinder to the other, or not to use a voltmeter.

The thermocouples have to fit a 12 mm spark plug. |

I

want a full sweep 3 1/8" tachometer and hour meter with

a maximum RPM of 5500, that will work with the 2 cylinder

electronic ignition. Sent e-mails to Aircraft Spruce, Westach

and UMA for info. |

Finished

covering the first aileron shrunk the fabric, and gave it

a sealing coat of Poly-Brush.

Gave

a coat of Poly-Brush to two more ailerons. |

|

|

4

hrs |

|

|

| 9 |

|

| Had

an answer

from Verner this morning: the oil pressure sender has a 10

x1 mm thread. Now I need to find out the size of the Mitchell

probe.

Also

received the 1/8"x 3"x 36" piece of 4130 steel.

It weighs 4 lbs . Drew the Lord mount support bracket on

it.

Gave

a second coat of Poly-Brush to the wood. Covered the other

3 ailerons . |

| Attached

adhesive 3/8" polyester rib reenforcing tape, and punched

holes in fabric every 2 1/2" , starting 1 1/4" from the spar.

Practiced rib lacing with the modified Seine knot. I think

I got it right, but will run it by Dick Simpson when I get

a chance. |

|

|

8

hrs |

|

|

| 10 |

|

Finished

rib lacing the first aileron. Put some Poly-Brush on the ends

of the 3/8" tape to keep them from unraveling.

Brushed

the seal coat of Poly-Brush on the other 3 ailerons.

Brushed

2 coats of Poly-Brush on stabilizer frame. Covered the stabilizer

with one single width of polyester wrapped around the trailing

edge and glued to the curved leading edge . Ironed seams

smooth, wiped all with MEK |

Put a

seal coat of clear Poly-Brush on top side of stabilizer.

Took

the Lord mount mounting plates to the tin shop to have them

cut and punched. The mounting bolts are 10 x 1.5 mm . |

|

|

8

hrs |

|

|

| 11 |

|

Cut

1/2 circles out of firewall and top of boot to make room

for my big feet . I quote Gene: " The front seat

of the Classic is not for you guys with big feet. Don't see

a problem cutting out a 1/2 moon and gluing in a piece of

3/4" ply cross member across the top of the cut out. Rather

then moving the mount down, I would cut out the top of the

cowl and glass in a couple bumps for the top of the carbs

to into. nicely shaped bumps in the cowl even look good some

times. ".

Cut

piece of 1/2" plywood to re-enforce firewall, and glued

it in place.Fitted

1/16" curved filler pieces. |

Got

an e-mail back from Westach suggesting I use the 3 1/8" Model

#Y3ATH7A tachometer/hourmeter, made for 2 or 6 pulse alternator

operated, 0-7000 RPM . It costs $208, plus red line markings. |

|

|

4

hrs |

|

|

| 12 |

|

Finished

fitting and glued in 1/16" plywood curved foot wells.

Cut

and adjusted metal covers, and glued them to plywood.

Notched

firewall and boot metal covers to fit . |

|

4

hrs |

|

|

| |

| 13 |

|

| Rib

laced ailerons . Decided that rather than doing the modified

Seine knot and running a continuous cord, it was easier to just

use a single lace with a square knot and 2 half hitches to lock

it. Then pull it inside, as shown above. |

|

Taped

ribs with Poly-Fiber light weight 2" pinked tape . It is

expensive, but looks better than the cheaper medium weight

tape I had bought first. And it matches the fabric exactly.

Started

rib lacing the stabilizer. |

|

|

4

hrs |

|

|

| 14 |

|

Finished

rib lacing the stabilizor.

Taped

the ribs with 2" light weight

Poly-fiber tape. |

|

3

hrs |

|

|

| 15 |

|

| Covered

elevator with a single piece of fabric wrapped around

the leading edge and overlapping at the trailing edge. |

Covered

one side of rudder , let it dry.

Ironed

seams smooth with 225 degrees iron, and glued other side

on. |

|

|

6

hrs |

|

|

| 17 |

|

Trimmed

fabric around rudder by pulling it against a sharp razor blade.

They wear out very quickly.

Ironed

seams flat at 225.

Cut

four 7" wide pinked strips of fabric to cover leading edges

of ailerons. |

Shrunk

rudder fabric at 250 and 350.

Gave

a seal coat of Poly-Brush to both sides of the rudder.

Taped

ribs with 3/8" tape. |

Shrunk

elevator fabric at 250 and 350.

Put

the seal coat of Poly-Brush.

Put

3/8" tape over the ribs. |

Rib

laced the rudder lace by lace with short pieces of lacing cord.

Pulled knots inside.

Glued

2" tape on top of laces. |

Cut

a square hole in top of gas tank to weld gas gauge flange.

Found

a nice old aluminum radiator cap with wings on e-bay that

will make a good gas tank cap. I will have to epoxy it to the

filler neck , mount a forward facing vent in the hole on

top, and find a soft rubber gasket. |

|

|

6

hrs |

|

|

| 18 |

|

Rib

laced the elevator.

Taped

ribs with 2" tape. |

Glued

a 7" strip of light weight fabric over the leading edge of

all four ailerons.

Glued

4" trailing edge tape on last two ailerons.

Trimmed

ends about 3/16" and wrapped around edges with Poly-tak. |

|

|

6

hrs |

|

|

| 22 |

|

Cut

a new set of 1/8" plywood nose ribs for leading edge

of defective wing.

Glued

them in place.

Wet

two 6"strips of 1/32"plywood and put them to

dry in the bending jig. |

|

|

3hrs |

|

|

| 23 |

|

Fit

the leading edge ply, marked ribs, and varnihed inside of

leading edge except for the glue lines.

Sanded

front rudder pedals wells, and varnished them, as well as

back of firewall. |

|

|

3hrs |

|

|

| 29 |

|

Installed

the covered stabilizor, elevator and rudder.

Made

one of the tail wires out of 3/32" cable and a turnbuckle. |

| Mounted

the elevator horn. Added a flat aluminum plate to increse the

mounting surface. Made two cardbord jigs at 20 degrees

and 25 degrees to check maximum travel of elevator: 20degrees

down and 25 degrees up. In order to get that with full

movement of the stick , I will have to use the middle one out

of the three holes pre-drilled in the horn. Riveted a rod end

to the push/pull rod, and used an Aurora bearing to connect

it to the elevator horn. |

Installed

trim tab and hardware .

Adjusted

the rod ends between front and back rudder pedals so the

front pedal would act as a rudder stop when they touch the

floor of the boot. |

|

|

6hrs |

|

|

| 30 |

|

Made

the rest of the tail wires using copper Nicopress sleeves

and brass turnbuckles.

|

I

will cover the piece of raw wire with a leather wrap.

|

| Glued

the wing leading edge plywood on. I find 1" masking tape does

a fine job of holding it tight untill the T-88 sets. |

|

|

6

hrs |

|

|

| TOTAL 837hrs |

|

|