|

| C

O N S T R U C T I O N L O G |

|

| A

U G U S T 2

0 0 4 |

|

|

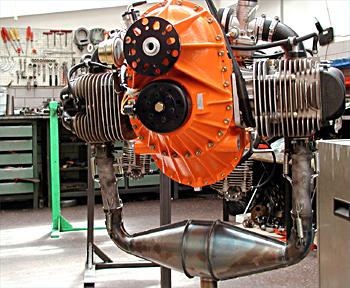

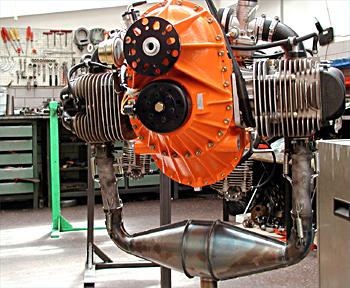

| The

goal (this is Stefan Wode's naked Classic in Germany) |

|

\

| 1 |

|

Flattened

tubes ends as per blue prints, but found they tend to crack

at the hole. I don't think T6 is meant to be crushed in a

vise. I will have to ask FFP if theyhave a new design, or

come up with a new way myself, like bolting 1/8" plates to

the side of the tubing. |

| The

front brackets do not seem big enough to me . They are identical

to all the other cabane brackets, which simplifies manufacturing,

but if I notch the heavily doubled tubes to fit around the

bolt ends, there won't be much material left around the hole.

I will order a piece of 1" channel and lengthen the bracket

so the hole can be moved down some. |

|

|

3

hrs |

|

|

| 2 |

|

Drilled

1/8" holes all the way around cockpit openings , 3/8 "

from the edge, to lace the future leather trimmed padding. |

Cut

out luggage compartment door in bulkhead behind pilot seat,

and made an aluminum door with aluminum piano hinge mounted

with brass screws.

Varnished

bulkhead, turtledeck, front seat, pedals, and rest of floor . |

| Experimented

with swirl patterns on aluminum using a 1" sanding disk

on the drill press. 120 grit seems to work best, with a staggered

5/8" grid. |

|

|

6

hrs |

|

|

| 3 |

|

Cut

a piece of padouk to panel size and planed it down to 3/32",

after attempting uncessfully to slice it in half . Drilled

3" holes to match 3 1/4" holes in plywood panel

, added 2 1/8" holes and matching 2 1/4' holes in

plywood .Mounted airspeed and vertical speed gauges with

brass acorn nuts. Looks real good! |

Sanded

overlapping circles on luggage compartment aluminum door

with 1" disk on drill press, sealed it with clear gloss

lacquer, and installed with brass screws and copper washers.

Looks real good!

|

| Cut

3" wide strips out of olive green leather scraps to use

around cockpit openings. Will have to mix 2 kinds to have

enough. |

| Made

two 24"x24" frames to stretch fabric on and test

clear dope finishes. |

|

|

8

hrs |

|

|

| 4 |

|

Added

missing blocks and ply gussets to top longeron at firewall.

Gussetted tank support, added spacers in front.

Varnished

the 2 frames.

Made

new larger brackets for front of cabanes out of 1" channel. |

Finished

cabanes , took down the plywood jig and put them back up

with 3/4" spacers between plates.

|

Installed

turtledeck aluminum pieces, cut holes to get cabanes through.

Worked

on cardboard pattern for front turtledeck. The holes for

the cabanes have to be very oblong. Cut 2" hole for gas tank

neck. Traced pattern on a sheet of .020 thick 6061T6 aluminum. |

|

|

8

hrs |

|

|

| 5 |

|

Cut

out of .020 thick 6061T6 aluminum the front turtledeck

cover. Light, but plenty stiff once bent around the curve.

Sanded

and varnished frames a second time. |

Cut

, fit , and install firewall aluminum pieces .

Spackled

and sanded elevator and stabilizer unit before second coat

of varnish. |

Cut

tentative cardboard patters for winshields. I like the

swept back look. A simple curved piece of plexiglass should

do it , attached to the turtledeck with small angle brackets.

Or better, a fitted copper piece all the way across the

bottom of the windshiels. The bent in the plastic should

keep it stiff enough.

|

|

|

10

hrs |

|

|

| 6 |

|

Cut

a padauk circle with a 2" hole to fit compass in aluminum

bullet I had , re-enforced with 1/16" plywood , and

mounted above panel on turtledeck in front of windshield

with two long metal screws through 3/8"x 3/4" tubes. Padded

interior with cotton to suspend compass and protect it

from vibrations.

|

Stretched

fabric on one of the frames after coating it with 2 coats

of diluted Poly-Brush. Used Poly-Tak to attach the fabric

, and pressed it down in the wet glue. Pulled it flat ,

but not tight. Messy, I need to get rubber gloves! I also

need to get an iron and a thermometer to calibrate it.

Sanded

and put a second coat of polyurethane on one side of stabilizer/elevator

assembly. |

Added

3/4"x2/4"brace to mount pilot throttle quadrant

lower , more or less at elbow level, where it fits comfortably

in the hand. The front quadrant will move down too, but

not so low as to interfere with the rudder pedal. |

Cut

and bent a 3/4"x1/16" aluminum strip and brackets to attach

bent plexiglas windshield.Cut out pattern out of an old piece

of 1/8" plexi .

I

may end up using a thinner and more scratch resistant polycarbonate

. Will use a 1" strip of brass or copper in front of the

plexi. |

|

|

8

hrs |

|

|

| 7 |

|

Made

5 small angled aluminum brackets to attach it to the turtledeck.Went

by the tin shop to have neat 1" copper strips cut.

Used a 1 " wide plexi strip as a spacer to drill the

holes through the copper, the alu strip and the brackets,

keeping everything nicely curving around the deck with

a good slant. Installed windshield. |

Added

1/4" spacer and 1/8"ply plate to bolt quadrants to. Installed

quadrants in new lower location. Much better, they fall

naturally under the hand.

|

Added

1/2"x1/2" strip on top of existing strip on top of boot

to have something to screw the aluminum firewall panel

to(the screws just went through the 1/8" plywood firewall). |

Debated

with Gib wether the trim lever I got would work the right

way: lever forward>push cable> tab up> elevator down>nose

down, seems OK. I guess I will use that locking lever even

though it is heavier than the advertized 8 oz. Glued a

1/4 strip to the side of the member to the right of the

pilot seat to be able to bolt to it.

|

|

|

8

hrs |

|

|

|

| Just

couldn't help! |

|

| I

have pretty much decided to do away with all the stringers that allow

to round out the fuselage, and just go for the boxy WW1 Nieuport look.

That would alow me to keep the varnished plywood sides and bottom exposed,

with decorative brass nails and screws, and may be a couple of brass

or copper strips to cover the fabric/plywood seams. I called FFP to

see if Gene sees any problems with that, and he seems to think it is

fine, even though he does not know of anybody having dispensed with the

rounding stringers. That should save a few pound and make up for some

of my cosmetic add ons. |

|

| 9 |

|

Installed

front windshield, same as back one, only smaller.

|

Installed

aluminum plate on floor below rudder pedals , and moved

pedal back and a little in so bolt would clear member.

Also had to trim the passenger seat a little on each side

so the toe brake bracket would not rub.

Shortened

travel of pedal by moving the bracket up about 1" to

the level of the hinge bolts. |

Made

right rudder pedal with toe brake to match the left one.

Shortened

push/pull rods so neutral position of pedals is more vertical,

so the toe brakes can be operated with full rudder. |

I

need to figure out the best way to attach the tail wheel

to the rudder push/pull rods. Just to see, I made two flat

1/2"x1/8" connecting rods attached to each side of the

rudder horn , and to the brackets of the tail wheel with

the supplied springs.Kinda works... |

I

got the idea from Buddy Tollison to use sheep skin guides

for the push rods, as was apparently done in olden times.

So I ordered some scraps from Tandy, and tried a piece

screwed to the seat cross brace. I may have to spray the

wool with WD40, or grease it, but it seems to work, and

Ilike the idea.... |

|

|

8

hrs |

|

|

| 10 |

|

Cleaned

up and organized tools.

Spackled

other side of stabilizer/elevator unit . |

Fit

plywood sides. Had to cut forward pieces a little longer

. Traced position of all longerons and members on the inside

. Drilled small holes at key locations to line up decorative

nails with center of members. Sanded all panels inside

and out.

Varnished

inside of panels except where they will be glued to the

frame. |

Cut,

fit rod ends with rivets and installed final linkage between

front and rear rudder pedals.

Cut,

fit rod ends and install final linkage for right rudder

pedal. |

|

|

8

hrs |

|

|

| 11 |

|

Gave

a second coat of varnish to inside of side panels except

where they are going to be glued to the frame.Gave

2 coats of varnish to outside of side plywood panels.

Sanded

and second coated other side of stabilizer/elevator unit

Attached

side panels with temporary screws and put cowling back

down over their top edge. Cut slots for wing attachment

to rear spar carry thru .

|

Trimmed

four 3/4"x1/4" stringers down to 1/2"x3/16" to glue to

geodetic in tail section so the fabric touches those instead

of the geodetic . I definitely like the way the light shows

the structure through the clear fabric in the picture,

and that confirms me in my desire to just clear coat the

fabric.

|

Made

new wider aluminum bracke.t

to replace the heavy steel bracket and attach the trim

lever. Installed the Bowden cable with fittings. Had to

enlarge the hole in the Bowden cable clamp to fit the 7/32"

casing and the hole in the B-nut to fit the .078 cable.

Tried

fitting the trim tab brackets with a B-nut and cable housing

clamp. My only concern is the short travel of the trim

tab lever in the cockpit . I may have to make a taller

bracket to mount to the trim tab to increase the lever

arm and therefore the travel . I could also drill a hole

closer to the axle of the lever in the cockpit. |

|

|

8

hrs |

|

|

|

I

am going to have to come to a decision about the engine. Looks like

the dream of the HCI Radial may be just a dream, as I can't find

anybody flying one... Considering the enormous cost of and the unproven

design , there is too much of a risk of failure. The Verner firing

only once per rotation gives me concerns about vibrations. The Jabiru

was actually tried on a Classic and did not cut it. The Rotec is

too heavy , and so are the VW conversions. I really don't want a

2 cycle.

That

pretty much only leaves the 80HP

ROTAX 912UL. It has a proven track record

in many airplanes, the 1500 hours TBO speaks for itself. It is expensive,

but should hold its value well, as there are no used ones to be

found anywhere. I was quoted $11250,

to which one must add the radiator, oil cooler, exhaust kit, engine

mount, etc... Gene is going to get me a price, but has no installation

instructions whatsoever. He has a motor mount design for the Dakota

Hawk that might be used as a departure point to make one for the

Classic.

I

sent an e-mail to Stefan

Wode in Germany to ask hin about his 912

installation. He seems to be the only one that has put a ROTAX

912 on a Classic, and since he just flew it to England, it must

be running pretty good! Hope I can pick his brains...

|

|

|

| 12 |

|

Made

and installed two aluminum backing plates for the third

cabane member. |

Used

iron to stretch fabric, first at 250F, then to 350F twice

. I used the littlecoiled spring thermometer, which seems

to work fine. Brushed a coat of Poly-Brush on one side,

glued rib tape and 1" pinked tape.

Brushed

a coat of nitrate dope on the other side, then a coat of

butyrate. Polybrush seems best, goes on smoother, doesn't

smell as bad. |

|

|

3

hrs |

|

|

| 13 |

|

Gave

a second coat of Poly-Brush, OUTSIDE !

Lined

up stringers on sides of geodetic tail section , and

glued in place , with little spacer blocks where necessary. |

Dave

Melvin came by to look the plane over, and seemed to like

it. He pointed out the pedals were narrow, which I know.

You have to fit two pedals and a seat in 24'',so you either

need very narrow shoes( I looked at driving shoes on the

internet) , or passengers with very small butts! Actually,

preferably both...Also, the bolts on the side of the rudder

pedals tend to catch on the vertical member. We looked

at a way to attach the brakes, either a bracket, or bolts

through the washer welded to the axle. Decided to drill

2 holes , after grinding away part of the lip, and bolt

them.

|

|

|

4

hrs |

|

|

| 14 |

|

Sanded

stringers and geodetic on tail, and gave a coat of varnish.

I will have to turn the fuselage sideways to do the bottom,

but first need to decide whether I leave it flat as the

sides, or round it, even build a fairing for the control

stick connecting rod that sticks out under the bottom of

the fuselage. I may have to make a turning jig to cover

it anyway.

|

Cut

and installed sheep skin guides for the push/pull tods,

screwed to wood blocks glued to the side of the bulkheads.

Started

designing the Artwork for the name of the plane: Spirit

of Thomas? Espiritu

Tomas? Spiritus Tomas? |

I

called Fisher about thee drums brakes being identical,

and Gene tried to sell me the new hydraulic disk brakes.

I would like them, but that's what I got, and will try

to do with them. Having trouble with the alignment of the

brakes though, that are not well centered with the wheels.

Loosening the screws attaching the drums helps , but I

don't like that much. If I were to go with new wheels and

brakes, I would love some big WW1 spoke wheels, so I did

some research on the net. Not much to be found , except

some nice sturdy 24" ones designed and made by Airdrome

Aeroplanes for WW1 reproductions. The only problem

is they cost about $250 each(not assembled) and also weight

18 lbs each! The wheels I have actually only weight 11

lbs... That would be 14 lbs extra, and would raise the

axles 5". I suppose I could extend the tail wheel

spring down... That would be the right look... |

| Moved

ball bearing on inside of rudder pedal bracket, so bolt head

does not catch on vertical member anymore. I could also replace

it with a clevis fork. |

|

|

5

hrs |

|

|

| On

this Sunday 15, I was feeling a little lazy , and just wanted to

see what the airplane looks like with the tail pieces and a wing

on . It is so nice and cool outside I just stuck the wing out the

door...Enjoy the pictures: : |

|

| I

then moved the fuselage over to the other table ,

so I can start working

on the wings. I have already got almost 400 hours in this project

already! |

|

|

| 16 |

|

I

am going to first finish the wing that Tom Hall built,

and make the aileron, before building the remaining 3 wings.

Glued

3/8"x1/16" strips to 1/4"capstrips on the top side of

the wing, to re-enforce the ribs(Fisher now uses 3/8" instead

of 1/4" capstrips), to make plywood leading edge wrap and

wing walk level with ribcaps, and to have a 3/8"wide rib

lacing stitch over 3/8" cotton tape. |

Started

shaping profile of wing tip bow.

Designed

Artwork for name of plane: the Spiritus Thomas . I will cut it

out of thin aluminum sheet and glue/nail it to the side of

the wood fuselage . |

|

|

4

hrs |

|

|

| 17 |

|

Started

on the aileron this morning, and finding a lot of discrepancies

between the blueprint and the reality. The aileron spar is

not quite wide enough (because the ribs are a little taller

than they should), and if I notch it by the blueprint, it will

be loose. The plywood end ribs for the aileron are on the small

side too, and the leading edge shape is more eliptical , which

diminishes the angle of travel up and down. Should I trim them

into a perfect circle as per blue print.

Also

wondering just how much clearance to leave on each side.

Chuck said 1/4" would be good.

I

went ahead and installed the hinges to see how the aileron

is going to fit and rotate, and what the gap is going to

be as it moves up and down . I cut a temporary

bevelled strip, and bevelled it at a sharper angle and moved

it back and forth until I got the best possible fit. That

gives about 1/4" gap

at neutral,almost no gap on top with aileron up 28 degrees,

and about 1/2" gap on top with aileron down 25 degrees. I

suppose that is satisfactory.

It

seems to me though that the gap could stay about the same

through the rotation if the hinge pin was moved further back

to the center of the circle. But that means the hinge would

have to extend farther and the hole in it be moved back too.

That would require new hinge brackets. I will make it work

with what I got! |

|

4

hrs |

|

|

| 18 |

|

| Cut

and glued 3/8"x1/16" strips on top of the 1/4" rib caps

on the other side of the bottom right wing. As the image

shows, no staples, as they would damage the narrow 1/4"

cap . and leave holes that are a lot of trouble to fill.

Small clamps, clothes pins and 1" masking tape do a better

job. |

| Bent

three 1/8"x3/4" strips in a nail jig to make an extra laminated

bow to attach to the top part of the flimsy 1/8" firewall

plywood. That will give someting to attach the alumunum

cowling to. I know I could glue the strips wet, but just

would rather let them dry first. |

|

|

4

hrs |

|

|

| 19 |

|

Got

a piece of 1/4" aircraft grade ply from the model shop

and cut 2 new larger end ribs for the aileron, mounted

the hinges, marked holes for pins in place, drilled

and installed pin hinges, glued the aileron spar and

end ribs in place .

While

it dried, I cut all the geodetic pieces and the 1/4"x1/4"

spar caps. |

| Sanded

everything smooth, and spackled leading edge ply with

aero-poxy to get a smooth flow into the rib cap strips. |

|

|

4

hrs |

|

|

| 20 |

|

Cut

new larger nose ribs out of 1/8' ply to match end ribs

and glued them in place.

Fit

and glued geodetic on the bottom side. It is not clear

from the blueprint whether there are 2 layers of geodetic

in aileron, but I will put two..

Cut

aileron off the wing. Notched trailing edge fill strip

to glue to rib ends.

|

Feathered

edges of wing walk.

Spackled

other side of leading edge ply with aero-poxy, as well

as the front and side of wing walk so the curve flows

smoothly into leading edge |

The

blueprint did not show any geodetic in the 3 cells next

to the aileron, so I added some after checking with Fisher.

Also

glued the geodetic to the compression members with

small spacers. |

| The

aileron hinges are a very basic 1/4" steel pin rotating

in an aluminum bracket drilled with a 1/4" hole . I am

concerned the aluminum will wear with time, and asked

Gene about using either a bushing or a ball bearing.

His answer was that they now had a stainless steel hinge.

That is better, and I could use it if it fits the existing

hinge holes in the rear spar. Dick Simpson used rod

end bearings in his Tiger Moth. |

|

|

6

hrs |

|

|

| 21 |

|

Sanded

ends of cut off ribs to fit curve of leading edge.

Cut and glued geodetic on other side of aileron. Glued

1/4"x1/4"

strips on the edge es of the 1/8" plywood aileron

spar , and 1/8"x1' plywood side stiffener.

Made

jig to bend 1/32" plywood for leading edge, wet 2 pieces

and placed them in to dry. |

Sharpened

bevel on the 1/4"x 1" trailing edge strip , cut 1/4"x1/4"

notches, dry fitted , trimmed ends

of ribs some to get proper clearance, and glued it to ends

of ribs and side of ribs at root end and tip end. |

Experimented

with painting/antiquing the fabric panel with a mixture

of Liquin and transparent artist oil paints . It had

been previously given 3 coats of Poly-Brush. Another

coat of or 2 of Polybrush should be enough to protect

it now. |

| Gave

one coat of varnish stain to the bottom side of wing,

the old fashion way, with a little bristle brush... Takes

for ever. |

|

|

8 hrs |

|

|

|

An

e-mail from Phil Miller in California is making me reconsider

the VERNER 133MK option. His pointed out that twin BMW

motorcycle engines run very smooth, and that I should not disqualify

the Verner just because it has only 2 cylinders. So I e-mailed

Kim Brown, who according to Gene is putting one on a Dakota

Hawk ,to get his take. His engine is the older 1400, which he

bought used on e-bay, and he has not run it yet. So I e-mailed

the distributor in Florida and am awaiting more info.The Verner

site shows an exhaust configuration that would work. iled

An e-mail from |

|

|

| 23 |

|

| Drilled

hinge bracket hole 3/8" and fitted bronze bushing in. I am a

little concerned about the strength of the aluminum around the

bushing. I would prefer a larger bracket. Gene is suggesting

to get the new all stainless steel hinges. |

| Fitted

the rod end bearings to the aileron push rods andL shaped lever.

Had to replace the sleeves. The problem I see is that the bearings

fit to the side of the lever and the lever might bind . I may

have to add a second lever to center the forces. |

| Got

from Aircraft Spruce a keyed 4 position ignition switch , and

a nice starter button with a rubber cover. |

|

2

hrs |

|

|

| 24 |

|

Varnished

other side of wing and aileron.

Dry

fitted 1/32" plywood leading edge of aileron and marked glue

lines. Varnished inside parts except for glue lines. |

| Laminated

firewall bow. |

|

5

hrs |

|

|

| 25 |

|

Finished

varnishing wing. Gave second coat to inside of aileron leading

edge plywood.

Screwed

beveled 2x4 to table and nailed trailing edge of right

top wing to it. Slid 11 ribs over front spar,and glued

them in trailing edge slots, using rubber bands to hold

them tight. |

| Glued

root rib to main spar against a block screwed to the table

so they are square. There was a 1/8" gap between the top

of the spar and the rib cap that was filled with a small piece

of 1/8" plywood. Even though Chuck said it was not necessary,

I decided to glue the 1/8" thick vertical member of the

ribs to the front of the spar. I want all the strength I can

get. |

| The

gas valve that came with the kit looks like a small ice maker

line valve ,and being installed just below the tank in front

of the passenger, it would be impossible for a pilot alone

to close it in case of an emergency. I found parts at Lowes

that will allow me to fit a 1/4" NPT ball valve , and

I will modify the lever to control it from the pilot dash with

a T-handle cable . |

|

5

hrs |

|

|

| 26 |

|

Glued

all ribs on main spar. Used 1/8" plywood spacers to fill

gap between top of spar and rib cap, with additional 1/32"

or 1/16' shims.

Slid

in rear spar , and glued ribs to it . Beveled a 1/8" strip

to make little wedges to fill gaps.

Trimmed

half ribs and glued them on. |

Glued

the two 1/4" beveled strips at the front end of the ribs .

Started

cutting and gluing in geodetic. |

|

8 hrs |

|

|

| 27 |

|

Finished

geodetic on top side of wing.

Glued

nose ribs, holding them in place with masking tape. |

Fit

and glued in wing tip bow, after notching first nose rib.

Added 2 blocks at each joint and a flat 1/8"x3/4" strip between

the last rib and the tip.

Cut

a bunch of 1/16"x3/8" strips to cap 1/4"rib caps. |

Glued

1/32" plywood leading edge of aileron . Masking tape worked

great to hold it in place to dry.

Wet

plywood for wing leading edge and put it in the trough to

dry overnight. |

|

8

hrs |

|

|

| 28 |

|

Turned

wing over , cut and glued 4 compression members with gussets,

and geodetic on bottom side of wing.

Started

buildind aileron. Cut 2 new larger end ribs out of 1/4" aircraft

plywood. |

Drilled

rear spar for wing attachment brackets. I should have done it

before on the drill press, but did not realize it had not

been done. Enlarged holes to 3/8" and glued in aluminum sleeves

for 1/4" bolts. Mounted wing attachment brackets to both

spars.

Cut

out end of root rib and part of the trailing edge to allow

for 45 degree cutout in wing and hatch. I would rather make

a larger rounded cut out with 2 layers of laminated 1/16"

plywood and may be dispense with the hatch altogether. It would

look better than that straight cut . |

Blew

up the design for the name on the computer and taped it to

the side of the fuselage to see how it would look . That

would be cut out of thin aluminum flashing material , glued,

and nailed with small brass or copper nails to the plywood

side . I might spell Thomas with no h as latin Tomas instead.

|

|

8

hrs |

|

|

| 29 |

|

Installed

hinges to build aileron, cut trailing edge to fit end

ribs, notched aileron spar and glued it in place with blocks.

Drilled end ribs for hinge pins and glued them to spar and

trailing edge.

Cut

and planed a bunch of 1/8"x1/2" strips out of larger stock

and cut geodetic for bottom side of aileron. |

Notched

front of trailing edge piece 1/4" and glued in the extra

plywood rib and doubler to attach aileron horn at midway

point of aileron.

|

Added

two extra 1/8" ply nose ribs were the 48" sections

of skin meet . Cut 1/32" plywood skin sections to fit . Taped

leading edge skins to the front ribs and marked the glue

lines on the back side. |

|

6

hrs |

|

|

| 30 |

|

Sanded

nose ribs for smooth transition to rib cap. Glued nose skin

sections in place and held them tight with a lot of strips

of 1"masking tape. I would rather do that than shoot staples,

which are more destructive, and then have to be pulled, and

leave holes that are a pain in the butt to fill.

|

Glued

aileron 1/4"x1/4" spar cap strips, and geodetic pieces on

the bottom side.

Glued

aileron nose ribs after cutting new ones out of 1/8" plywood.

|

Glued

the 1/16"x3/8" strips on top of the 1/4" rib caps. Taped

those on too instead of stapling.

Talked

to Gene about a round top wing opening instead of the 45

degree cut and no hatch, and he is OK with it. Cut a piece

of 1/8" ply to make curve. |

|

8

hrs |

|

|

| 30 |

|

Glued

more of geodetic on top side , as well as aileron spar cap

pieces. |

Glued

1/16"x3/8" strips on rib caps on top side of wing. Marked

scallops using Tom Hall's template, and cut them with a sharp

knife.

|

Sanded

and spackled lower right aileron leading edge and ribs.

|

| Cut

out an S out of the thin aluminum flashing and realized it

was too flimsy, so I cut the letters out of .035 thick cowling

scraps . They look nice, but I will need more aluminum. |

|

8

hrs |

|

|

| TOTAL 475

hrs |

|

|