|

| C

O N S T R U C T I O N L O G |

|

| J

ULY 2

0 0 4 |

|

|

| The

Goal (this is Stefan Wode's naked Classic in Germany) |

|

| 1 |

|

| Finished

gluing stringers and blocks for rear turtledeck . |

| Cut

and glued 1/2"x1/2" diagonal braces between bulkheads

in fuselage. |

Glued

in place back of main panel and front panel.

Dry

fit wrap around plywood sheets for turtledecks. |

| Mounted

brass hinge on back seat with brass screws. |

|

|

7

hrs |

|

|

Let's

take a look at my engine options. I ran across this great italian engine

link: http://ultraligero.net/Sitios/Motores/motores.htm ,

and checked out all the manufacturers.

I want

to get an air cooled 4 cycle engine , and a radial would look and sound

more authentic on a WW1 style biplane. |

|

|

The

factory Classic uses the 2 stroke Rotax

582 on the left.

They

seem happy with it, I just don't like 2 strokes much.

If

I were to go with a Rotax, I would prefer the 4 cylinder/4 cycle Rotax

912 , which is the engine on the Klein Classic now. But

it is water cooled, so needs a radiator, water, etc...I would prefer

an air cooled engine. |

|

|

|

|

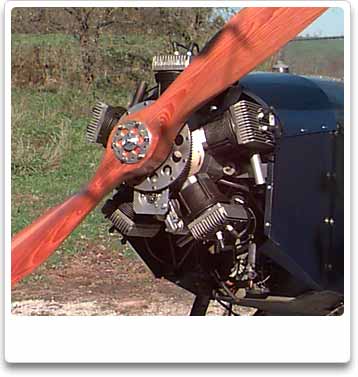

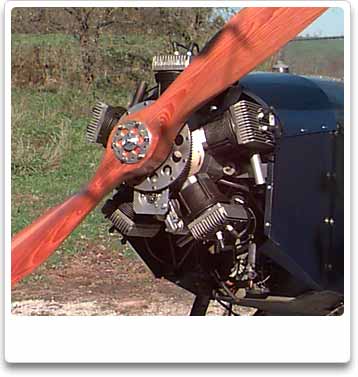

The

best looking and most exciting engine by far is the australian

made ROTEC Radial:

http://www.rotecradialengines.com

What

a beauty. Looks just like the old Gnomes. They offered to sell

one to me for $12500. Unfortunately, Gene says at over 200lbs,

it is too heavy for the Classic. Makes me wish I had built the

Celebrity! Somebody is actually putting one in a Celebrity, check

out : http://www.rotecradialengines.com/customers/phill.htm

Total

swept volume of 2800cc .

110HP

@ 3700 RPM geared.

Total

engine diameter is 810mm (31.9")

Dry

Weight with Accessories (Starter Motor + Alternator + Carb) = 102

Kg

If

there ever is another plane built, this will be the engine on it! matched

taper. Propeller flange specs |

|

|

|

There

is another radial actually made in the US by HCI:

http://www.hciaviation.com

It

uses VW cylinders and

pistons, and comes in 5 or 7 cylinders versions:

Horsepower 123

@ 2500 rpm for the 7 cylinders,160lbs

Horsepower 75

@ 2150 rpm for the 5 cylinders, 122lbs |

|

Gene

seems to think the 5 cylinders R180 would be a possibility, though

he is concerned about drag. The kit is about $10000, the assembled

engine $12000.But that is without carburator, exhaust, etc... |

|

|

|

Another

option being tried on 2 Classics at the

moment is the Verner 2 cylinders boxer made in Tchecoslovaquia:

http://vernermotor.com

http://centralfloridaflyers.com

1329

cc / 85.13 cubic inch

Maximum

Power 84HP @ 5500 RPM(3mn max)

Maximum

continuous Power: 70

HP@ 4200 RPM

Torque 88ft/lb

@ 4200 RPM

Reduction

gear box 1:2 or 1:2.29 Weight

61kg including all accessories

|

|

|

| |

|

| 2 |

|

| Trimmed

scallops to fit and glue 1/16" turtledeck ends |

| Cut

1/4" threaded rods and glued them in holes to hold panel with

acorn brass nuts. |

Added

two 1/16" ply strips bent under stringers for added rigidity.

|

Put

tail feathers in place to fit hardware.

Sorted

out hardware for tail feathers assembly. |

|

|

6

hrs |

|

|

| 11 |

|

| Mounted

rudder horn. Added an aluminium backing plate. |

Added

gussets to front part of rudder.

|

| Added

1/16" rib caps and strips over edges to make everything

level to stretch the fabric on. |

|

|

4

hrs |

|

|

| 12 |

|

| Added

1/16" rib caps and strips to elevator. This will allow a smooth

fabric surface, as well as re-enforce ribs, and stiffen elevator. |

| Planed and sanded rudder smooth Planed

and sanded rudder smooth. |

|

|

4

hrs |

|

|

| 13 |

|

Glued

in uprights for passenger seat back to floor and back of panel.

Glued

together sides of seat. Glued

front seat in.

Added

gussets on inside of fuselage. |

|

|

6

hrs |

|

|

| 14 |

|

Fit

seat and back.

Started

drilling and assembling joystick and torque tube. |

|

|

6

hrs |

|

|

| 15 |

|

Worked

on joystick and torque tube assembly.

Made

and installed all 4 rudder pedals. |

|

|

6

hrs |

|

|

| 16 |

|

Finished

and polished joytick assembly.Turned fuselage on its side

to install it. Drilled floor and rear carry thru with hole

saws. Started installation .

Spacked

rudder with Aeropoxy Light. |

|

|

6

hrs |

|

|

| 17 |

|

Glued

block to rear spar carry thru to attach elevator control

lever behind pilot seat. |

| Installed joysticks and elevator control rods. |

Installed

tail wheel support and stabilizer braces brackets on lower

longerons.

Disassembled

landing gear and started polishing parts. |

|

|

6

hrs |

|

|

| 18 |

|

Added

1/16"strips all around edges of stabilizer.

Sanded

rudder and varnished it with Olympic poly-urethane varnish

stain .

Started

adding 1/16"strips to stringers on rear turtledeck. |

|

|

4

hrs |

|

|

| 19 |

|

Planed

and sanded 1/16" strips on stabilizer and elevator, spackled

with Aero-poxy.

Added

more 1/16" strips to stringers and tail fin.

Sanded

airframe, geodetic , etc...

Ordered

seat belts, Poly-fiber materials to test covering , replacement

aluminium tubing, throttle quadrants, and washers. |

|

|

8

hrs |

|

|

| 20 |

|

Sanded

elevator and stabilizer. Spackled other side.

Sanded

airframe.

Called

Fisher to clarify mounting of landing gear and position of

members on top of floor thru which it bolts. |

| Glued

those members on top of floor and directly above longerons

on each side. |

Added

large gussets to attach throttle quadrants I just received

from Aircraft Spruce.

Cut

slots for passenger seatbelt to attach inside panel.

Sanded

airframe. |

|

|

8

hrs |

|

|

| 21 |

|

Mounted

landing gear on with only 4 x1/16" bolts. That somehow does

not seem like much.

|

| Installed

the pilot throttle quadrant using longer screws. |

Added

blocks and plywood backing to attach stabilizer.

|

|

|

4

hrs |

|

|

| 22 |

|

Installed

second throttle quadrant, and made linkage out of 3/8" tubing

and rivetted clevis forks.

|

Paid

a visit to Dick Simpson( he is my EAA advisor and is building

a Fisher Tigermoth himself) to look at his plane and pick

his brains. He has hydraulic toe brakes on his plane, and

I just adapted the pedals to my purpose.

He

used cables for rudder connections, and I know it is the

traditional way. But as an engineer , I can't help thinking

rods with ball bearing ends would give a better linkage,

so I rigged it my way and will let him and the guys look

at it Tuesday. |

To

test my theory without ruining an expensive 3/8" 6061T6 tube

, I threaded the ends of a 1/4" aliminum rod I had and screwed

the rod end on.

It

seems to work pretty good to me. |

|

|

6

hrs |

|

|

| 23 |

|

The

pedals were toofar forward, even for my long legs, so I moved

them 4" back to the next member in the floor.

Installed

brake cable between pedal and go kart drum brake. |

Ordered

4 Aurora bearings with a 3/16" hole and 4 rod ends to fit

3/8" tubing.

|

Installed

passenger seat belt as per plans. But the fit is awkward,

and I can't buckle the belt . I will have to use a cable

extension, or make anothe anchor point to the side of the

seat.

|

|

|

4

hrs |

|

|

| 24 |

|

Varnished

elevator and stabilizer with Olympic poly urethane varnish

stain to replicate the look of old orange shellac.

Sanded

and varnished forward floor section and pedals, as well as

the area of the front of the firewall to be covered with

metal. |

Put

a second coat on rudder. Spackled fin and turtledeck stringers

with Aeropoxy.

Glued

angled pieces in fin.

Loosened

up and lubricated stick assembly to move smoother. Could

still be better. Need to get teflon blocks for the

push rod to slide through. |

|

|

4

hrs |

|

|

| 25 |

|

Drilled

2 1/2" holes in seat backs. Varnished .

Linked

front pedal to back one . |

|

|

3

hrs |

|

|

| 26 |

|

Sanded

and varnished floor and frame, panels , etc...

Cut

and installed angle brackets to connect seat belt bolt

under passenger seat to side of seat . |

Drilled

blocks for pilot seat belts and cut slots in seat to get

the belts through.

Cut

slots to attch rear spar to spar carry -through. |

Cut

and install new angle brackets to attach front of stabilizer.

The ones that came with the kit were drilled too close to the top.

Varnished

inside of geodetic and turtledeck, and fin. |

|

|

10

hrs |

|

|

| 27 |

|

Got

ready for first inspection by Dick Simpson, EAA advisor,

and John Burgin, field inspector for the FAA certification

. They looked the plane over, and seemed pleased with the

quality of the work. Dick will send a report to the EAA,

that he says should help me get insurance from them.

Installed

new tail wheel I had ordered from Fisher to replace the

flimsy grocery cart wheel that came with the kit. |

Bought

a few sheets a poster board and started cutting patterns

for the aluminum turtledeck panels. |

|

|

5

hrs |

|

|

| 28 |

|

Cut

and fit aluminum turtle deck panels out of 6061T6 .032 .

Cut them with an air nibbler , and sanded edges smooth using

a particle board pattern to support metal.

Used

small copper side pieces with stainless finishing washers

and brass screws. |

Cut

3 1/8" holes in panel with hole saw, and installed air speed

and vertical speed non TSO instruments from Aircraft Sruce.

Used small brass acorn nuts. Will add a 3/16" thick padauk

veneer. |

|

|

10

hrs |

|

|

| 29 |

|

Screwed

turtledeck panels down with brass finishing washers.

Decided

to use a lighter .020 weight 6061 T6 aluminum for the front

turtle deck , with supports over the gas tank. |

After

talking to Chuck at FFP, I cut out the dropped down gas tank

support members and raised them back up level with the top

longerons. That way, the stick doesn't hit the bottom of

the tank anymore and there is more room for my knees in the

passenger seat. Used 1/8" ply gussets under the members and

the longerons . |

Riveted

1/4" rod ens to 3/8" tubing with 470AD(hard) 3/32" aluminum

battering rivets for final left rudder connection.Used 2

at each end at right angle to each other. Moved

temporary rod to the right side to make rudder functional

and test the pedals. It gets a little too far for the toe

brake when the rudder is all the way on that side. The pedals

may have to move back a little more, or the connecting rod

will have to be shortenned some to bring the pedals back.

I may move the connecting bracket up to shorten the travel

of the pedals. |

Mounted

the three steel hinges on stabilizer and elevator.

Made

trim tab cable brackets.

Sorted

out the pieces for the cabanes. |

|

|

8

hrs |

|

|

| 30 |

|

Polished

and shaped all brackets for cabanes, cleaned up tubing.

Cut

and assembled cabanes jig out of straight 3/4" plywood. Added

plywood squares.

Fitted

jig on top longerons 25 5/8" back from firewall. |

Got

some good black rubber pipe insulation and experimented with

lacing a padded leather trim around the cockpit openings

through 1/8" holes drilled along the edge of the metal turtledeck

pieces. Tje smaller one will be my choice, using short pieces

of soft leather stitched end to end to follow the curve. |

|

|

8

hrs |

|

|

| 31 |

|

Polished

tubing for cabanes, attached doublers on end with 1/8" pop

rivets.

Put

in place brackets with one bolt only, placed tubes ,

drilled and assembled cabanes, except for the front top

brackets which I find too small. Notching that heavily

doubled front tubes to fit would leave so little material

it would not be safe in my book. I will order some 1" channel

and make slightly larger brackets.

|

Had

to move back the gas tank that I had just moved up. Will

rebuild the support members. |

|

|

4

hrs |

|

|

| |

Total

Hours so far |

308hrs |

|

|

|