|

|

|

|

|

5hrs |

I bolted the engine on, and connected the choke cables, the accelerator cable, and instrument wires.

I cut oblong holes in the bottom of the cowling to exit the oil hoses going to the cooler, which is attached to the front of it, right in the prop wash, and is held almost vertically away from the bottom of the cowling with 2 brackets. I used nylon hoses to do the fitting, and ordered from Aircraft Spruce 5 feet of 1/2" Aeroduct MIL-DTL 6000 oil and coolant hose, which is more flexible than the Aeroquip hoses, which is what I need . The oil outlet being in the very back of the engine in the firewall, the hose has to turn 180 degrees to go forward to the cooler.

I also decided to install an emergency electric pump , and ordered the smallest Facet pump. It will be connected to the gascolator and the mechanical pump with sections of 1/4" gas hose. The engine distributor recommended against leaving the pump on all the time, so I added a switch and a blue light to the panel above the main switches, and wired it to the front of the firewall.

|

|

|

|

|

|

8hrs |

I assembled the plane outside again with the engine and cowling on, to do the weight and balance. I put it up on blocks fitting the slope in the driveway, and leveled the top longeron and the wings. I started with an old scale, but it was not accurate, so I bought a digital bathroom scale that went up to 330 lbs, which is actually just barely enough with somebody in the cockpit. I checked it using 1, 2, 3, 4 and 5 Gls of water , and found it accurate( it reads in increments of .5 lbs.

I chose the axle as the DATUM. As it happens, the plane in level flight position is perfectly balanced on the front wheels, with no weight at all on the tail wheel, and that is where the empty center of gravity is. The weight on the left wheel was 253 lbs, on the right 268 lbs. That is an empty weight of 521 lbs, a lot more than the 400 lbs quoted by Fisher. I was expecting to be heavier, my landing gear added about 35 lbs, and the engine about 20 lbs, but I don't know what the rest came from. I did add a lot of trim, a full instruments panel, leather cushions, but then I did not use fabrics to round out the fuselage, and my paint job is very light... I had hoped that would even out... There isn't much I can do about it now, except declare the plane a single seater if necessary. Tests will show.

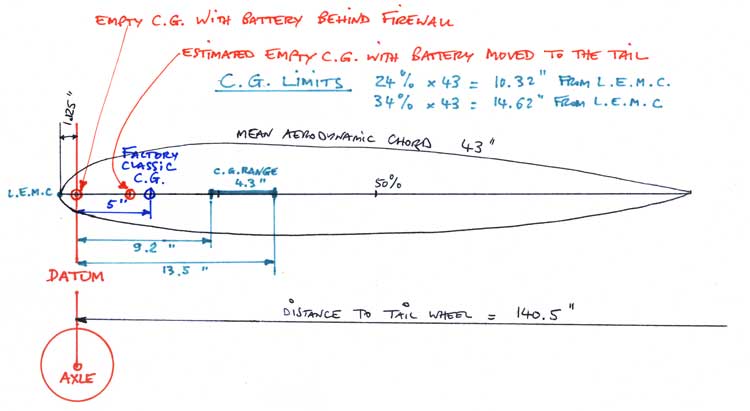

I called Gene at Fisher, and his empty weight is 450 lbs, with 16 lbs on the tail wheel. That means they have an extra moment backward of 16 lbs x 140.5"=2248, placing their empty C.G. : 2248 / 450 = 5" aft of axle.

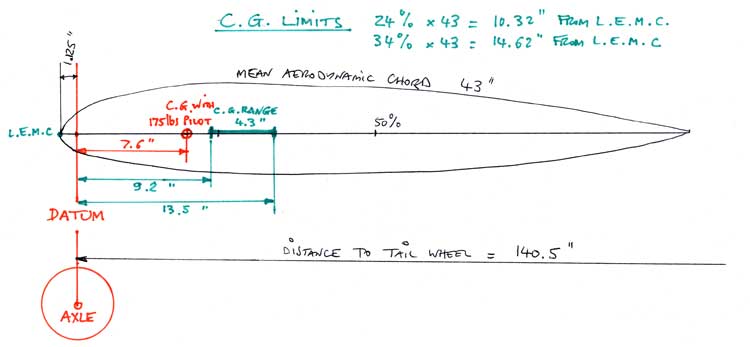

I decided to use the axle as the Datum for the rest of the weight and balance. I used a vertical level to mark a piece of tape on the ground with the leading edge of both wings , and the half way point is the leading edge of the median chord. This fell 1 1/8 " forward of the Datum( vertical center of axle). The center of gravity limits are 24% and 32% of the median chord, which works out as +9.2" and +13.5" aft of the Datum. That is only 4.3 " between most forward and most aft position of C.G., not a whole lot... Obviously, the empty center of gravity is way out of range, but on a plane with a payload equal to the empty weight , it probably never is. Anyhow, what really counts is the C.G.loaded and ready to fly.

So I sat in the cockpit while my godchild read the scales. The figures corrected for tare were: LEFT WHEEL 330.5 lbs, RIGHT WHEEL 315 lbs, TAIL WHEEL 37 lbs. That gives a total weight with pilot of 682.5 lbs. Something is off, as I weight in at 175.5 lbs and the empty plane is 521 lbs. The scale is beyond its upper range of 300 lbs, and not accurate. Total weight should be 696.5 lbs. I will buy another scale and do the next weight in with 2 scales bridged with a plank. The front wheels are on the DATUM, so it actually doesn't matter for the calculation, since the moment of the weight on the main wheels is zero. The distance from the DATUM to the tail wheel is 140.5", so the backward moment of the tail is 37 lbs x 140.5" = 5198.5 , which places the C.G. 5198.5/682.5 = +7.6" from Datum, 1.6" too far forward of the most forward limit +9.2". As the EMPTY WEIGHT AND BALANCE already showed, I have a nose heavy problem, and full gas and oil will make it even worse.

The gas tank holds 8 Gls of gas, or 7.5lbs x 8 = 48 lbs, creating a forward moment of : -(48 x 16") = -768

The engine and cooler require about 1 Gl of oil, which weights 7.5 lbs. The approximate forward moment of the oil is: -(7.5 x 61") = -457.5

The total additionnal forward moment of both is therefore -1225.5, which would move the C.G. further out of range forward : -1225.5 / (696.5+48+7.5) = -1.6"

NOT GOOD...

I know a substantial portion of my extra weight is in the new landing gear, actually about 35 lbs , and that extra weight is forward of C.G. Let's calculate whether replacing it with the rather flimsy original gear would substancially help. But I am running into a mathematical problem here if I use the Datum at the axle . Those extra 35 lbs are right there on the axle, so their moment is 0 , so if we follow this reasonning, the weight of the gear does not matter, which does not seem correct. But where is the catch there?

To make my point, let's for a moment move the Datum 24.5" forward to the firewall . The C.G. with pilot would therefore be 7.62 +26.5' = 34.1" from the new Datum. The moment of the whole airplane would be : + 696.5 lbs x 34.1= 23750.65 . Going back to the 35 lbs lighter gear would remove a moment of: 35 x 34.1 = 927.5 , which would give a new moment of 22823.15, for a new total weight of 696.5 - 35 = 661.5 lbs. The new C.G. would be: 22823.15 / 661.5 = 34.5" from new Datum , or .4" more aft, a good thing, but not enough to give up my beautifull $500+ gear... Anyhow, why do I get a different result moving the Datum? Anybody out there can tell me?

| WEIGHT | ARM | MOMENT | |

| AIRCRAFT | 521 | 26.5 | 13806.5 |

| PILOT | 175 | 57.5 | 10062.5 |

| PASSENGER | 200 | 30.5 | 6100 |

| GAS | 48 | 12.5 | 600 |

| OIL | 7.5 | -33.5 | -251.25 |

| Total | 951.5 | 30317.75 |

Without the passenger, the figure would be 24217.75 / 751.5 = 32.2", which is still out of range.

The C.G. has to be moved back at least 3".

| WEIGHT | ARM | MOMENT | |

| AIRCRAFT | 521 | 26.5 | 13806.5 |

| PILOT | 175 | 57.5 | 10062.5 |

| OIL | 7.5 | -33.5 | -251.25 |

| Total | 703.5 | 23617.75 |

There seems to be no choice but to move the battery as far back in the tail as possible . I will cut a flap open on 3 sides in the side of the tail to re enforce a platform for and install the battery. The edges of the flap will be re enforced, holes made every inch with small grommets, and the flap laced back tight, as seen on many WW1 fighters.

I did not take into account in the calculations the weight of the two #4 cables needed to connect the battery, but their effect on the C.G. would be in my favor. To be precise, two 13 ft cables weight : .160 lbs x 26 ft = 4.2 lbs( #6 cable would only weight 2.7 lbs, but is probably not sufficent on that length). Three feet of wire are forward of C.G. , and ten back . The two 3 ft sections would cancel out, so the averaged moment of the most backward 7 ft would be : .160 lbs x 7 ft x 78" =87.4. That would move the C.G. back : 87.4 / 525 = .17", a good thing.

|

|

|

|

8 hrs |

I cut a flap in the side of the tail as far back as the battery would fit . I re enforced the edges of the flap on the inside with 3 strips of 1" dacron tape.

To get the battery in, I had to cut two pieces of 1''x 1/8' geodetic, and a 1/2' x 1/2' diagonal brace. I will replace them with re enforcement before closing the flap. The battery requires no maintenance and should last years. I will just cut them again when it needs to be replaced...

I cut a tight fitting cardboard pattern for a triangular piece of plywood fitting on top of the two bottom longerons from the tail block to the strut braces. I need some extra weight back there anyway, so I cut the battery platform out of 3/8" plywood, and glued it with T88 to the longerons, the tail block in the back, and the strut brace in front. I cut and glued on top of it a U shaped piece to hold the battery front and sides. I made a copper strap to hold the battery down, that attaches with small screws to the 1/2" x1/2" braces on each side.

I glued a 1' wide piece of wood to support the fabric at the tail end of the flap, between the two longitudinal strips. I drilled holes in the wood strips around the flap and put eyelets in. I punched holes staggerred with those around the opening every inch around the 3 sides of the flap and crimped in eyelets.

I glue a 1/2" x 1/2" brace and 2 geodetic strips back in where they had been cut . I varnished all the new wood.

|

To make it easier to check oil levels and add oil, I cut a hole in the top piece of the cowling and fitted a hinged door. It is held in place with 2 wing studs. | 5hrs |

|

|

|

|

|

10hrs |

I ordered two 25 ft rolls of #4 automotive battery cable , one red and one black. The white only aircraft cable was just too expensive at $2.90/ ft . I first soldered terminals on the back ends. I then ran my 2 cables along the left side of the fuselage and secured them with small plastic clamps and ties. I decided to run them directly to the relay and the starter in front of the firewall, and to run 2 short cables back to the battery jump posts on the side of the plane.

| L A S T M O N T H | I N D E X | N E X T M O N T H |